Elena Gómez-Sánchez,* Simon Kunz and Stefan Simon

Rathgen Research Laboratory, National Museums Berlin, Schlossstr. 1A, 14059 Berlin-Charlottenburg, Germany. E-mail: [email protected]

Introduction

The Music Archive of the Ethnological Museum (National Museums Berlin, Germany) houses, among other collections, a large number of recordings on phonograph cylinders and magnetic tapes. The project ILKAR (Integrated Solutions for Preservation, Archiving and Conservation of Endangered Magnetic Tapes and Cylinders, http://www.ilkar.de) aims at prioritising the digitisation of the more than 10,000 magnetic tapes of the Archive. With the Rathgen Research Laboratory as the other main partner, this project was launched in 2008.

In this article, the usefulness of attenuated total reflection/Fourier transform infrared (ATR/FT-IR) spectroscopy for the characterisation of the constituent materials of magnetic tapes is discussed.

The final aim of the project is the identification and characterisation of the most endangered materials of the Archive’s collection and an evaluation of their state of conservation.

The information obtained through this study will allow the development of a prioritised digitisation strategy within the Music Archive of the Ethnological Museum. Also, due to an online tool, other archives will also be able to use the results in order to design their own, material-based, digitisation workflow.

The preservation of magnetic tapes

Since the first commercial magnetic tapes were developed in Germany in the 1930s for the recording of sound, millions of hours of recordings have been stored in archives all over the world. The 20th century saw a rapid succession of formats being developed and then cast aside after a relatively short period of time (typically a few decades). Amongst the most common and studied of them is reel tape, an example of which can be seen in Figure 1.

The recording mechanism of magnetic tapes relies on a magnetic layer capable of “storing” the sound by retention of the magnetism impressed on them by the recording head. This layer is sustained over a base film, which provides structural support. Different materials have been used over time as base films, with cellulose acetate (CA), poly(vinyl chloride) (PVC) and poly(ethylene terephthalate) (PET) being the most widespread. A polymeric binder keeps the magnetic layer particles attached to the base film while holding them together, and lubricants diminish the friction between the tape and head in the magnetic layer on playback. Other components of magnetic tape formulations are typical additives of plastic materials, such as plasticisers, stabilising agents such as antioxidants, dispersants, antistatic agents and mineral fillers which, in the present case, are often used to achieve the desired hardness, flexibility or adhesion on the final manufactured magnetic tape. However, each of these components can potentially have an impact on the final behaviour and long-term stability of the tapes. In fact, some of these materials are not stable with time and information is eventually lost, unless it has been transferred to digital form in time. Two well-known decay mechanisms are the so-called “vinegar syndrome” and “sticky shed syndrome”, affecting acetate based tapes and polyurethane binders in the magnetic layer, respectively.

Both processes are intimately related to the inherent stability of the materials and triggered by ambient humidity. In advanced stages, both mechanisms render the tapes unplayable, posing a deeper problem than the loss of a single tape. In the case of cellulose acetate tapes, the cellulose acetic acid released on decay, which is responsible for the name of the phenomenon (vinegar syndrome) may potentially catalyse the degradation of other, not yet affected tapes stored nearby. It therefore becomes essential to identify and isolate these materials before the problem spreads, as well as transferring the recorded information they contain as soon as possible.

On the other hand, low molecular weight products arise as a result of the hydrolysis of certain polyurethane (PU) binders (sticky shed syndrome) which migrate to the surface of the tape. These degradation products may inflict damage on the playback devices which, given their obsolescence, are difficult to repair, putting in danger, to some degree, the digitisation of the whole collection. In this respect, poly(ester urethane) (PU-ES) binders are assumed to be more susceptible to hydrolysis than their polyether (PU-ET) counterparts.1

The condition of most types of less-severely affected tapes can be stabilised under a controlled atmosphere. To achieve this, relative humidity and temperature need to be maintained within certain levels2 in order to avoid the appearance of mould and to slow down the rate of the different degradation processes.

As with many other modern materials, however, once these processes have started, even in the best of cases they can only be slowed down in appropriate conditions, but not reversed. Moreover, these processes usually become noticeable once the damage is so widespread that digitisation of the information cannot be completed without consequences either on the quality of the copy, on the playback devices or on the tape itself.

Unfortunately, in many cases, the information on damaged tapes can never be retrieved again and is thus lost forever. From time to time, certain “surprises” allow one to only guess the real size of the “iceberg”—the amount and importance of what becomes lost in endangered audiovisual media all over the world due to the numerous problems affecting them, be it obsolete formats or material damage.3

When dealing with originals, it therefore becomes clear that time management is essential. However well aware of this fact they may be, archivists and sound technicians in charge of these collections are usually left alone with the problem.

The music archive of the Ethnological Museum of Berlin houses, among other collections, a large number of unique recordings on magnetic tape, focusing on historical and contemporary music from all over the world. The total play length of all original, non-commercial audiovisual recordings is now estimated at more than 12,700 hours. The key question is: where to start with the digitisation? In other words, which tapes must be transferred now on the basis of the stability of their materials and which will remain in an acceptable condition until the information in the most endangered ones has already been transferred?

This is the starting point for the ILKAR project. This project aims at applying a range of non-invasive techniques in order to find markers for degradation and develop criteria and workflows which will enable a more efficient use of the available timeframe. In this work, ATR/FT-IR spectroscopy is proposed for the non-invasive characterisation of the main components in the formulation of both binders and base materials of reel tapes. The identification of the more sensitive materials following this approach will allow the development of a timely, rationally designed digitisation strategy in order to target more endangered materials first.

Survey

A systematic and representative sampling procedure was designed within the framework of ILKAR in order to acquire a good impression of the most common and the most endangered and damaged materials. Five hundred and seventy-seven tapes were surveyed; from those, over 150 were chosen for analysis with ATR/FT-IR spectroscopy, both on the basis of representativeness with respect to the results of the survey and trying to account for the different degradation states present. Several tapes from each main type were analysed.

Analyses were performed on both sides of the tapes, so that information on the binder in the magnetic layer and of the base material could be obtained. The analysis of the front side, the “information layer”, allowed studying of the polymeric binder in the magnetic layer, while analysis of the reverse side allowed the analysis of the base material in those samples without back-coating. Given the thickness of the layers, the low penetration depth of the ATR technique ensures that both sides can be analysed independently. Figure 2 shows a typical layer constitution of a magnetic tape in a reel tape. The cross-section shows the magnetic or information layer (here ~25 µm) on which the magnetic particles are embedded in a polymeric binder, along with other components such as lubricants, while the similarly polymeric base film (here ~35 µm) can be seen below the former.

Each measurement was performed on the first few millimetres of tape, where no sound is supposed to be recorded (Figure 3). In any case, the pressure induced by the contact head of the spectrometer could be controlled due to a spectrometer software command and set to not exceed a certain value, which had been previously set up as acceptable.

Identification of base and binder materials with ATR-FTIR

The infrared analysis of the information layer side allowed the identification of PVC, PU or mixtures of both as the prevalent polymeric binders. Poly(ester urethane) binders are known to be involved in the so-called sticky shed syndrome. On the other side, PVC, PET and cellulose acetate were identified as base materials. The distribution of the materials in the archive, as analysed with ATR/FT-IR spectroscopy, is shown in Figure 4. In the design of a rational digitisation strategy, poly(ester urethane) binders (13%, left diagram) would have higher priority than materials where poly(ester urethane) could be present but could not be identified unequivocally [i.e. groups “PU unclassif” and “PVC + PU”]. Both groups would, in turn, have a higher priority than the rest of the materials. In the case of base materials, cellulose acetate (3%, right diagram) would have higher digitisation priority than the rest.

![Figure 4. Distribution of materials in the archive [binders, (a); base materials, (b)].](/sites/default/files/articles/IR-24_01-F4.jpg)

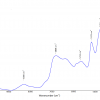

Among non-marked tapes the occurrence of poly(ester urethane) was interesting. Figure 5 shows a typical spectrum. Characteristic bands4 shared with the reference polyurethane are 3317 cm–1 (N–H stretch), 2921 cm–1 and 2864 cm–1 (C–H stretch), 1726 cm–1 and 1698 cm-1 (C=O stretch, free and H-bonded, respectively), 1595 cm–1 (NH bending or aromatic C–C stretch), 1528 cm–1 (C=N stretch, N–H bending), 1413 cm–1 (C–C stretch, aromatic ring), 1308 cm–1 (C=N stretch, NH), 1219 cm–1 (C=N stretch, NH), 1167 cm–1 and 1075 cm–1 (C–O–C stretch). The main difference in the infrared spectrum of a poly(ester urethane) compared with a poly(ether urethane) spectrum is in the C–O–C stretching frequencies. While a poly(ether urethane) will show a very intense double band at around 1100 cm–1 for the C–O–C antisymmetric stretching of the polyether and urethane moieties, the corresponding frequencies in the spectrum of a poly(ester urethane) will fall in the same region but showing a particular pattern between 1250 cm–1 and 1150 cm–1.

Table 1 relates the polymeric materials identified by ATR/FT-IR spectroscopy in the analysed tapes to the producer and tape types. To establish this relationship, only brand names printed on the back of the tape were taken as reliable. The information should be used carefully, since the formulations sometimes have been changed without changing the name. As an indication, the number of tapes analysed which helped linking a given formulation with a tape type has been included in the last column. Although information on the base materials used for the manufacture of some tape types exists, for some producers5 such information was generally missing for binders.6

Tape type | Binder material | Base material | No. of analysed tapes | No. of surveyed tapes |

AGFA Gevaert PEM 468 Professional | PVC and PU | * | 11 | 117 |

PU-ET | 7 | |||

AGFA PEM 468 Professional | PVC and PU | * | 5 | 12 |

BASF PEM 468 Professional | PVC and PU | * | 4 | 23 |

VEB Filmfabrik Agfa Wolfen Typ CH | CN | CA + TPP | 2 | 2 |

Sony-Tape Super-5 | PVC and PU | PET | 1 | 1 |

Sony-Tape PY-5 | PVC and PU | CA | 4 | 4 |

Toshiba sound tape s-5 | CN | CA + TPP | 1 | 1 |

Regarding base materials, the identification of cellulose acetate tapes is usually positively established in archives all over the world if the tape reel is translucent when observed against a light source. However, this rule of thumb does not always seem to work unequivocally.7 Using ATR/FT-IR spectroscopy, tapes could be analysed which presented a translucent tape pack having base materials other than cellulose acetate. It could also be confirmed that cellulose acetate-based tapes are indeed translucent, except in advanced degradation stages, where they turn opaque.

In order to make this information available for other archives, the collected data was transformed into a browser-based database, which has been designed to aid in establishing correlations between brands/tape types, materials and (early) degradation signs.

The database was designed for different kinds of users. First of all, archivists who want to establish a prioritised digitisation strategy. For example, they may want to know how endangered a tape of a given type is, by considering the materials it contains compared with other tape types in the archive containing materials which are not so sensitive. For archivists with a large amount of reel-to-reel tapes in their archive‘s holdings, the database provides the possibility to enter one’s own data and use the online database as a survey tool. Due to this, the database can also be enhanced by increasing its statistical strength. Finally, scientists can improve the database by completing the analytical data for the largest number of possible different tape types. Archives or individuals interested in gaining access to the database may contact Albrecht Wiedmann at [email protected] for more information.

Conclusions

ATR/FT-IR spectroscopy has been used non-destructively for the analysis of information-containing magnetic tape materials without compromising the sound quality. It is a key technique in distinguishing typically unstable (i.e. endangered) materials such as poly(ester urethane) binders and cellulose acetate as base material from relatively stable ones within collections, allowing a timed digitisation of the unique information the holdings contain.

The information obtained through this study will allow the development of a prioritised digitisation strategy in the archive, as well as help in dealing with tapes with no brand specification. A representative number of spectra of the most characteristic tape materials will be made available for reference purposes on the ILKAR website and/or in the IRUG collaborative FT-IR Library database of artists’ and related materials (see: http://www.irug.org/ed2k/about.asp).

The results have also been made available in the form of an online tool to other archives and professionals, who can now design their own material-based digitisation strategy.

Future work within ILKAR will include degradation studies of different tape materials by comparison of the FT-IR spectra of tapes in different conservation states.

Acknowledgements

The authors would like to thank the “Kulturstiftung des Bundes” (Federal Cultural Foundation) and the “Kulturstiftung der Länder” (Cultural Foundation of the German States) for the financial support of this study.

PerkinElmer, especially Mr Hoffman, and the University of Applied Sciences, Potsdam, are gratefully acknowledged for the use of an ATR/FT-IR spectrometer.

The content of this article is based on the following publications, where this research was first published:

“ATR-FTIR Spectroscopy for the characterisation of magnetic tape materials”, E. Gómez-Sánchez, S. Simon, L.-C. Koch, A. Wiedmann, T Webe and M. Mengel, e-Preservation Science 8, 2–9 (2001).

“ILKAR: Current research towards the assessment of the conservation state of magnetic tapes in archives”, E. Gómez-Sánchez, M. Mengel and S. Simon, ICOM-CC 16th Triennial Meeting, in ICOM-CC 16th Triennial Conference Preprints, Lisbon, 19–23 September 2011, Ed. by J. Bridgland, Lisbon, Portugal. Critério–Artes Gráficas, Lda, Setúbal, Portugal (2011).

References

- http://prestospace.org/project/deliverables/D6-1.pdf. PrestoSpace Deliverable 6.1; D6.1: Report on Video and Audio Tape Deterioration Mechanisms and Considerations About Implementation of a Collection Condition Assessment Method (D6.2). Last accessed 07.02.2012.

- International Standard Organisation (ISO) 2006 #1910. Imaging Materials—Magnetic Tape: Care and Handling Practices for Extended Usage, ISO 18933. Geneva, Switzerland.

- http://bavc.org/why-analog-to-digital-video-preservation. Why Analog-to-Digital Video Preservation, Why Now, Last accessed 07.02.2012.

- J.R. Schoonover, D.M. Dattelbaum, J.C. Osborn, J.S. Bridgewater and J.W. Kenney, III, “Pressure-dependent Fourier transform infrared spectroscopy of a poly (ester urethane)”, Spectrochim. Acta A 59, 309–319 (2003).https://doi.org/10.1016/S1386-1425(02)00173-7

- F. Engel, G. Kuper, F. Bell. Zeitschichten: Magnetbandtechnik als Kulturträge, 2nd Edn. Polzer Media Group GmbH, Potsdam, Germany (2010).

- E. Gómez-Sánchez, S. Kunz and S. Simon, “Useful and simple tools for priorizing digitization in small archives”, in Futre Talks 011: Technoogy and Conservation of Modern Materials in Design, Papers from the Conference held at the Pinakothek der Moderne, Münich, Germany 26–28 October (2011), in press.

- S. Kunz, E. Gómez-Sánchez and, S. Simon, “A closer look on translucent tapes” in ILKAR Project Documentation (DVD), Ed. by L.-C. Koch and S. Simon. ILKAR, Berlin, Germany (2011).