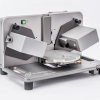

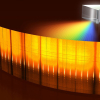

Canon Inc. has announced the development of the first practical-use germanium immersion grating, making possible a significant reduction in the size of infrared spectrometers used in astronomical and other applications. Germanium immersion gratings cover the germanium transmissive frequency range of the infrared spectrum between approximately 3 µm and 11 μm. Compared with conventional reflective diffractive gratings, immersion gratings make possible higher dispersion relative to the refractive index.

With the new grating, spectrometers could be drastically reduced to approximately 1/64th their current volume while maintaining the same levels of performance as the high-dispersion infrared spectrometers now employed in large telescopes. This, in turn, could support the launch of satellites equipped with high-performance spectrometers and make possible spectrometers for next-generation large astronomical telescopes that are smaller in size or enable higher levels of performance than those employed in astronomical telescopes currently in operation.

Canon will supply its germanium immersion gratings as products and intends to market them to astronomical observatories and research institutes for use.

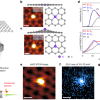

While the benefits of fabricating immersion diffractive gratings were realised long ago, because the transmissive material employed in the field of astronomy for infrared frequencies (from 1 µm to 30 μm) is semiconductor material, it is extremely brittle. As such, attempts to achieve a surface of virtually perfect regularity with grooves measuring only a few nanometres proved difficult. Canon’s ultra-precision processing technology, developed through the manufacture of precision components, was applied to single-crystal germanium resulting in a practical germanium immersion grating with 100-μm grooves at regular intervals measuring just a few nanometres.

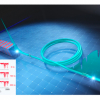

Aside from its germanium immersion grating, Canon also developed the first cadmium zinc telluride immersion grating, capable of covering a broader spectrum and longer wavelengths of infrared light. In the future, the Company intends to not only create immersion gratings with other infrared semiconductor materials, but also to improve the performance of conventional reflective diffractive gratings. Through the addition of immersion diffractive gratings made from various materials to the Company’s product line, Canon aims to facilitate the analysis of substances of differing refractive indexes and wavelengths, enabling a wide range of applications for infrared spectroscopy, not only in the field of astronomy, but also in the fields of science and medicine.