Dried snack foods such as apple chips are a convenient alternative to fresh fruit, providing longer shelf life and easier storage. Consumers increasingly demand product variety, so companies coat such snack foods with fruit and vegetable powders to enhance taste and sensory appeal.

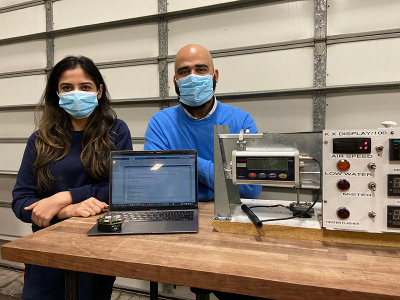

A new study from the University of Illinois explores the drying process of coated and uncoated apple chips using near infrared (NIR) spectroscopy to measure moisture content in real time. NIR technology greatly enhances the speed and accuracy of measurements, the researchers say. The purpose of coating is to make dried apple chips more functional and nutritional, as well as more appealing to eat, explains Ragya Kapoor, graduate student in Food Science and Human Nutrition (FSHN) at the University of Illinois.

“The idea is to get school-aged children to include apple chips in their diet. We use a cranberry powder coating to make the apple slices more attractive in terms of colour and taste”, Kapoor says. “We dip the apple slices in a liquid-based solution for 60 seconds twice, and then conduct the hot air-drying operation.”

The researchers check the moisture content at various points throughout the drying process with miniature NIR spectroscopy to ensure the chips are dry enough. NIR technology offers many advantages compared to standard monitoring techniques, says Mohammed Kamruzzaman, assistant professor in the Department of Agricultural and Biological Engineering (ABE).

The team had two main research goals. They wanted to explore edible coating on apple slices and test the use of NIR spectroscopy to monitor the drying process for coated versus uncoated slices.

“The moisture content is different for coated and uncoated samples, and we wanted to see how drying behaviour differs for them. We found that with NIR technology we are able to differentiate between the two samples based solely on the difference in their composition”, Kapoor explains.