Elke Thisted

PhD, Manager Process Control & Development On-Line Analysis, Glencore Nikkelverk AS; Head of organisational committee for WCSB10

UN Sustainability Development Goals

The UN sustainability goals are now spreading throughout society, showing us the way to the future. Everybody wants to contribute to a more sustainable world. Sometimes, actions to support sustainability are presented as easily comprehensible tasks for society, i.e. saving energy and lower emissions. It would appear that almost all companies’ management can present a portfolio of sustainability related projects with a clear understanding of which sustainability development goals (SDGs) they support.

It takes time ... and insight

Sometimes, however, other tasks are necessary to move this development demand forward: more insight and knowledge. Sometimes such tasks are hidden in the background of more pressing everyday needs (pandemic, climate crisis, inequality etc.). This is precisely the situation for appropriate sampling, which is, nevertheless, a critical success factor for sustainability.

Some companies, unfortunately, show a lack of recognition of the importance of appropriate sampling and only see this as an unnecessary expenditure. It is necessary to be able to point out how correct sampling can contribute to reach our common, as well as the individual company’s, sustainability goals. All companies, of course, seek to run their production efficiently, but far from all prioritise the quality of the data necessary to optimise this business goal. And, if so, new investments are typically much more easily allocated to better analytical systems in the laboratory, sadly foregoing or neglecting the importance of the first step of all analytical processes, appropriate sampling. But as one strives for a lean production, optimisation of processes, more efficient use of resources and fast correction of process deviations are highest on the prioritisation agenda. Therefore, it should be a no-brainer to see appropriate sampling as an important foundation to reach such goals.

Appropriate sampling must be brought in

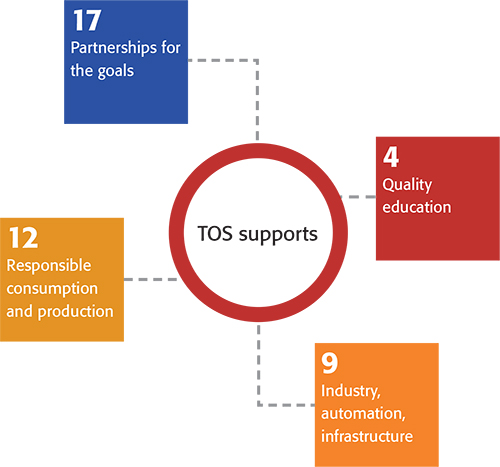

To bridge the gap between the science behind the TOS and applied industrial procedures, let’s connect appropriate sampling to four of the 17 SDGs:

4: Recognising the importance of applying the TOS in your company is the first step. This can be done most efficiently by educating employees, on any relevant level, to understand better the quality of the data that is being used for process monitoring and control (QA/QC), i.e. knowing the origin of the valuable data, as well as their uncertainties. Increased knowledge on sampling error contributions is crucial here—all is not only analytical uncertainty! Investing just a little for this purpose will immediately enable increased sound critical thinking around current procedures.

9: A mind set aiming for continuous improvements should a.o. contain the willingness to rethink current sampling procedures in any company or organisation. Sampling protocols should not be static, but dynamic, in order to follow increasing knowledge and experience in the TOS arena and the most recent technological developments. New emerging industries, especially, should have a clear mission including optimal sampling.

12: A key factor is process understanding and optimisation. For this, it is necessary to have trustworthy sampling schemes, which ensure that the data utilised are indeed correct (representative) and can be used to follow all relevant process improvements. If this is not the case, the righteous chase for improvements will include many unnecessary trial-and-error loops, unavoidably also leading to lower motivation in the organisation and to quite unwarranted data distrust.

17: Creating awareness around the existence and application of the TOS is the ultimate goal of the International Pierre Gy Sampling Assocation (IPGSA), which has been put into action by the biannual World Conference of Sampling and Blending (WCSB) series, by the magazine TOS Forum and by a regular sampling column in Spectroscopy Europe/World. Networking individuals, companies and organisations and regulating authorities in these fora in the last 20 years have spawned immense activities, very fruitful discussions and learning across all almost sectors in science, technology and industry.

How to reach the SDGs most efficiently?

We have all the right tools at hand for appropriate sampling.1–9 The TOS has been out there for seven decades, although its impact has been especially effective since the change of the Millennium. This work is very well under way.

In the last two decades, ten World Conferences on Sampling and Blending have promoted the TOS to a continually broadening community, far from all sampling experts “by birth”, and has connected users and suppliers of sampling equipment in a highly efficient way. Also, many educational courses from sampling experts have been given, making the TOS’ principles much more approachable to “common users” in technology and industry. Very many articles have been published that highlight the importance of a basic understanding of what makes sampling representative. And standards and guiding documents have been approved to lead the way towards representative sampling, e.g. the de facto international standard DS3077.1

A personal impression: Compared to the extensive literature that is now available at all levels,1–7 from introductory (very easy to understand by all) to the highest textbook level,8–9 the marked impression regarding the heading: “How to reach the SDGs most efficiently?” is …. that relevant individuals, scientists, company employees, organisational personal, management etc. DO NOT HAVE THE TIME, OR DO NOT SET ASIDE THE NECESSARY TIME FOR CONTINUING SELF-EDUCATION (please observe that the effect hereof is one-and-the-same). Here is a call to all involved in the sampling business: We are all individually obligated to start doing better—not much is required for a first step!

Still, today, there would appear to be a lack of focus on appropriate sampling across many sectors in technology and industry. There is much focus on process improvements and innovation, but little, far too little, on how the crucial data with which to control the process are obtained. Sampling and its related activities is a critical success factor and a vital support function for production processes, which should never be forgotten or neglected. And, N.B., the TOS is valid both for traditional physical sample extraction and for process analytical technology extracting sample characteristics through appropriate sensor technologies. Any chain is only as strong as its weakest link!

So, dear CEOs, managers, supervisors …

- Strengthen your sustainability drive(s) and start actions to control the crucial aspect of sampling!

- It is what you run your processes with!

- Your bottom line depends on it!

- The current planet is in danger—and requires appropriate action!

- Remarkably, appropriate sampling has a role to play even in this vastly larger perspective!

- It all starts with me and you!

References

- DS 3077. Representative Sampling – Horizontal Standard. Danish Standards (2013). https://www.ds.dk

- TOS Forum (freely available) https://www.impopen.com/tosf

- Sampling Column in Spectroscopy Europe (freely available) https://www.spectroscopyeurope.com/sampling

- AusIMM literature https://www.ausimm.com/insights-and-resources/resources/

- SAIMM literature https://www.saimm.co.za

- WCSB Proceedings https://intsamp.org/proceedings/

- K.H. Esbensen, Introduction to the Theory and Practice of Sampling. IMP Open, Chichester, UK (2020). https://doi.org/10.1255/978-1-906715-29-8

- F.F. Pitard, Theory of Sampling and Sampling Practice, 3rd Edn. CRC Press, Boca Raton, Florida (2019). https://doi.org/10.1201/9781351105934

- G.J. Lyman, Theory and Practice of Particulate Sampling: an Engineering Approach (2019). http://materials-sampling-and-consulting.com

Elke Thisted

Elke Thisted has worked as the Manager of Online Analysis & Development at Glencore Nikkelverk in Kristiansand, Norway, since September 2018. She studied Chemistry at the Technical University in Karlsruhe, Germany, from where she was awarded a MSc (chemistry) in 1998. She received a PhD degree from the Norwegian University of Technology and Science in Trondheim in 2003 in the field of impurities in aluminium electrolysis. From 2004 to 2014 she worked in Elkem, Norway, on method development (measurement, processes and products). Since 2014, she has worked at Glencore Nikkelverk as Lead Process Engineer responsible for process mapping and improvement based on Nikkelverk’s business system (LEAN). She has since then worked with variography to broaden applications in the process industry, applying experiences and knowledge gained “in-action” to Glencore Nikkelverk’s Online analysis framework. Thisted joined the IPGSA council in 2017 and is currently the head of the organisational committee of the 10th World Conference on Sampling and Blending, which will be held in June 2022 in Kristiansand: www.wcsb10.com

[email protected]